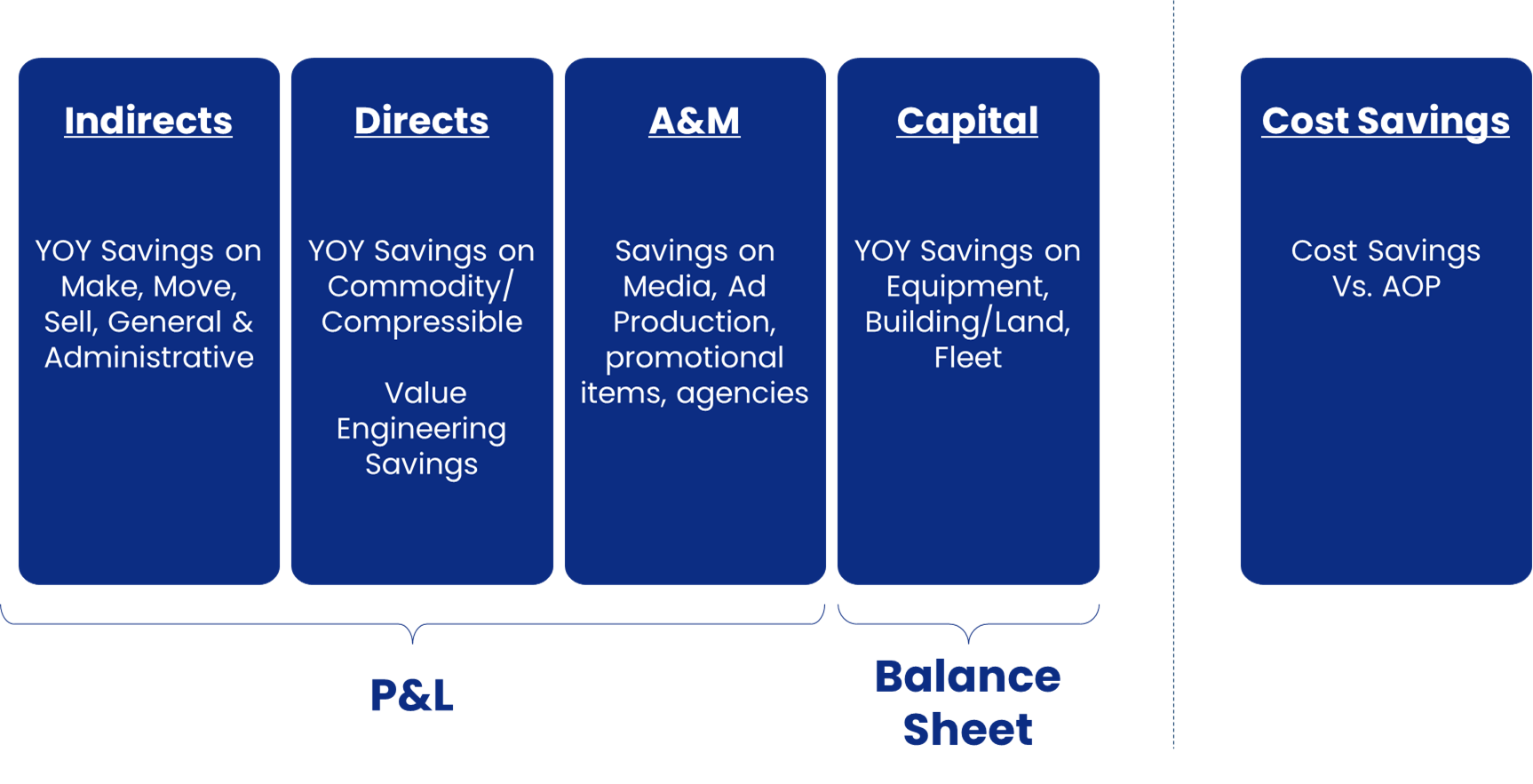

Key Definitions Critical to Understanding Cost Savings

1. DEFINITION OF “PRODUCTIVITY”

Productivity denotes cost-saving efforts that result in Year over Year (YoY) reductions in fixed and variable expenses, excluding any effects from volume leverage. To qualify as reportable productivity initiative, there must be an established historical baseline for the initiative.

2. YOY PRODUCTIVITY DRIVERS

Two Levers Drive YOY Directs Productivity:

- Reduction in negotiated rates (cost per unit) YOY and/or Conversion Cost Rates (Direct) YOY

- Reduction in input costs through Value Engineering initiatives

3. PRODUCTIVITY SAVINGS AMOUNT

Productivity Savings Amount:

(YoY change in cost per unit) * (# of units purchased in the current year), (CY rate - PY rate) * CY volume

Conversion calc = (YoY change in conversion rate per unit) * (volume in current year)

Value Engineering calc = (YoY change in input material cost per unit) * (volume in current year)

4. TOTAL COST OF OWNERSHIP

The YOY Productivity includes Total Cost of Ownership (TCO) and must be validated by Business Finance. TCO is the guiding principle of productivity Net of inflation & incremental costs.

5. PRODUCTIVITY REPORTING

PoweerSteering serves as the main platform for tracking all savings initiatives, including productivity improvements, cost reductions or avoidance, and it is the sole site used for reporting these savings.