Pepsi Productivity Framework

Key Definitions Critical to Understanding Cost Savings

Principles of Productivity

What are the key principles of recognizing Productivity?

- Ensure YOY Productivity

- Based on tangible cost reductions over comparable Prior Year (PY) baseline

- Follow Total Cost of Ownership (TCO) as a guiding principle

- Net of inflation & incremental costs to achieve productivity

- Includes total delivered costs (e.g., Duties, Freight & Taxes), Rebates and Penalties

- Record 12 months rolling Productivity

- Validate Productivity calculations with Business Finance

- Must be in PowerSteering (productivity reporting system)

- Volume reduction in value engineering/total project cost/efficiency/optimal use of resources due to intentional changes and action taken can be counted as productivity. Fluctuations in volumes due to simple business changes/supplier mix is not productivity

Types of Productivity

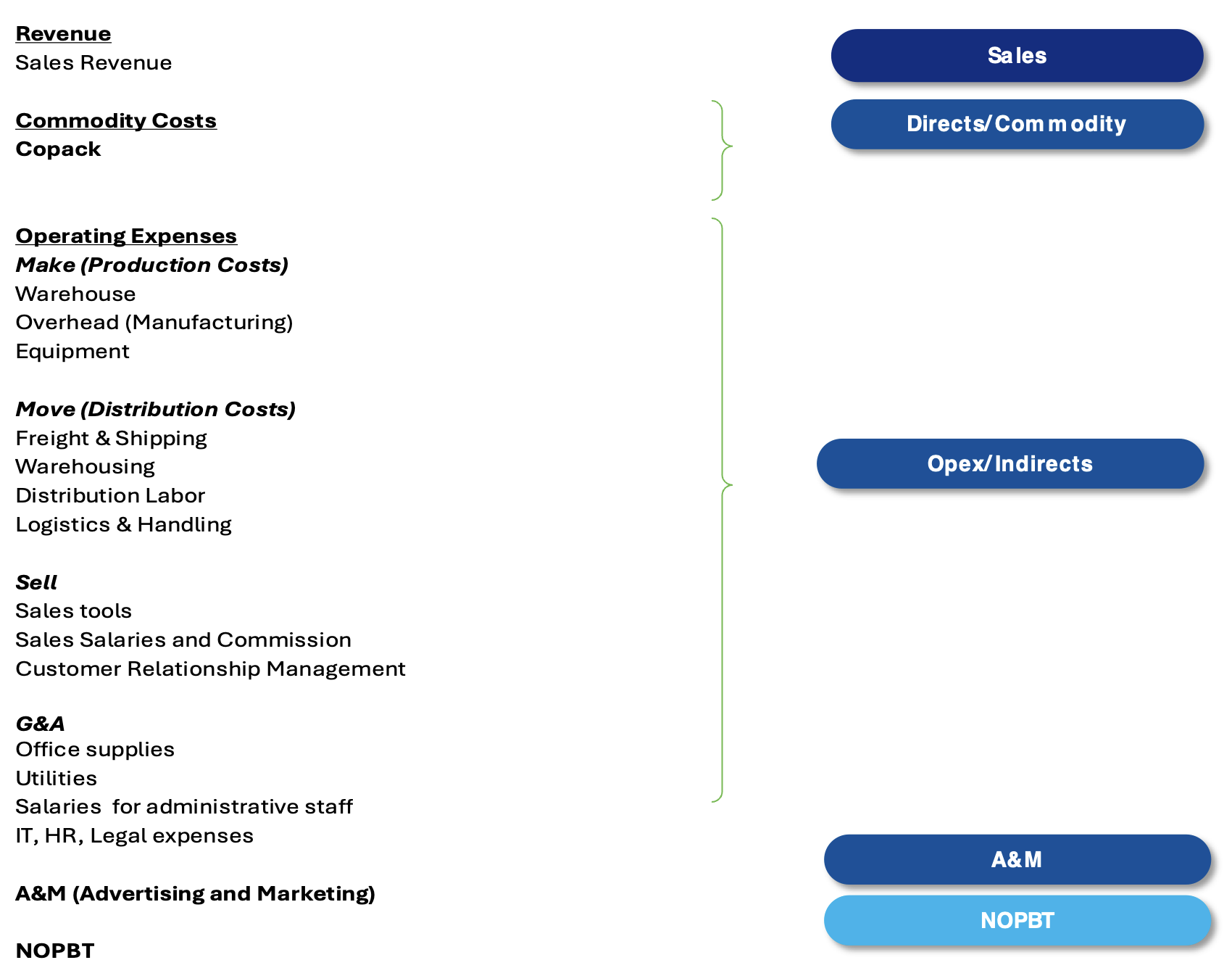

Productivity is generated across almost all lines within P&L?